Introduction to Electric Drive Systems

Electric drive systems are revolutionizing the way we think about transportation and industrial applications. From electric vehicles to automated machinery, these systems power our modern world in ways that were once unimaginable. But what exactly goes into making an electric drive system work seamlessly? The answer lies in three key components: motors, controllers, and power supplies. Each element plays a vital role in ensuring efficiency, reliability, and performance.

As industries continue to pivot toward greener technologies, understanding these components becomes essential for anyone involved in design or implementation. Whether you’re an engineer looking to optimize your projects or a curious enthusiast wanting to learn more about how things work behind the scenes, this guide will unravel the intricacies of electric drive systems. Join us as we dive deep into their core elements and explore why they matter more than ever before!

Overview of Motors Used in Electric Drive Systems

Motors are the heart of electric drive systems. They convert electrical energy into mechanical power, enabling movement in various applications.

The most common types of motors include brushed DC motors, brushless DC motors, and AC induction motors. Each type has its unique advantages suited for different needs.

Brushed DC motors offer simplicity and ease of control but require maintenance due to wear on brushes. Brushless DC motors provide higher efficiency and longevity since they eliminate brushes altogether.

AC induction motors are popular in industrial settings for their robustness and ability to operate at high speeds. Their design allows them to handle varying loads effectively.

Choosing the right motor is crucial for optimizing performance in electric drive systems. Factors like torque requirements, operating environment, and energy efficiency play a significant role in this decision-making process.

Types of Controllers for Electric Drive Systems

Controllers play a crucial role in electric drive systems. They manage the flow of power between the motor and other components.

There are several types of controllers available, each designed for specific applications. Pulse Width Modulation (PWM) controllers are popular due to their efficiency. They regulate voltage by turning it on and off rapidly, ensuring precise control over motor speed.

Field-Oriented Control (FOC) is another advanced technology used in high-performance applications. FOC provides smooth operation by controlling both the magnitude and direction of torque production.

For less complex tasks, simple on-off controllers may suffice. These basic models offer straightforward functionality but lack fine-tuning capabilities found in more sophisticated options.

Choosing the right controller depends on factors like application requirements and budget constraints. The perfect match enhances system reliability while maximizing performance potential.

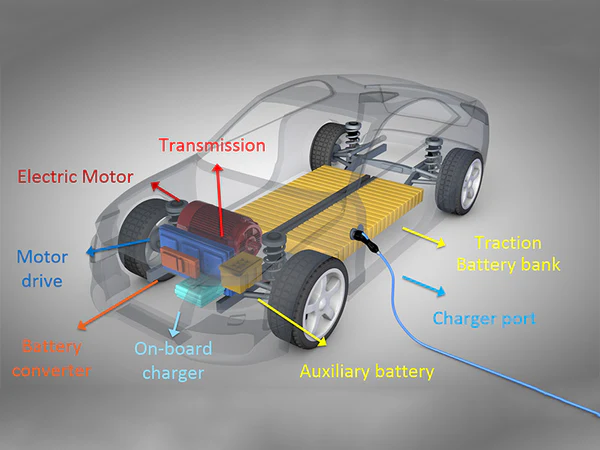

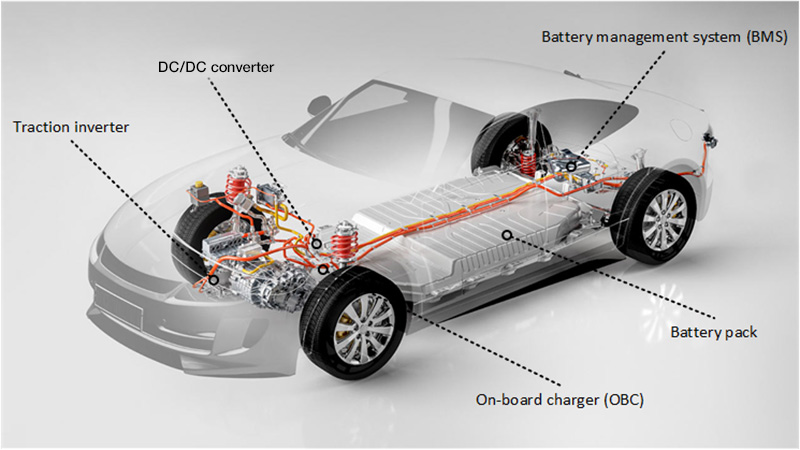

Power Supplies in Electric Drive Systems

Power supplies are the backbone of electric drive systems. They provide the necessary voltage and current to keep everything running smoothly. Without a reliable power supply, even the most advanced motors and controllers would struggle.

There are various types of power supplies used in these systems. AC/DC converters, for instance, transform alternating current from the grid into direct current suitable for electric drives. Battery packs also serve as portable power sources, particularly in mobile applications like electric vehicles.

Efficiency is key when selecting a power supply. The right choice can enhance performance and reduce energy losses. Designers often consider factors such as load requirements and environmental conditions.

In addition, safety features should not be overlooked. Proper insulation, overload protection, and thermal management help ensure that electric drive systems operate safely under different circumstances.

Importance of Choosing the Right Components for Optimal Performance

Selecting the right components is critical for achieving optimal performance in electric drive systems. Each element, from motors to controllers and power supplies, plays a pivotal role in ensuring efficiency and reliability.

When these components work harmoniously together, they enhance overall system responsiveness. This synchronization minimizes energy waste while maximizing output.

Moreover, using appropriate parts can significantly reduce maintenance costs. High-quality components often ensure longevity, sparing users from frequent replacements or repairs.

In applications ranging from electric vehicles to industrial machinery, performance hinges on precision selection. An ill-suited motor or controller can lead to inefficiencies that ripple through the entire system.

Investing time upfront in choosing compatible components ultimately pays off with smoother operation and increased productivity over time. It’s an essential step that shouldn’t be overlooked by engineers or end-users alike.

Common Challenges and Solutions in Electric Drive Systems

Electric drive systems face a range of challenges that can hinder their efficiency and performance. One significant issue is thermal management. Motors generate heat, which can lead to reduced lifespan or failure if not properly managed. Implementing effective cooling solutions is vital for maintaining optimal operating temperatures.

Another common challenge involves compatibility between components. Mismatched motors, controllers, and power supplies can disrupt system functionality. Ensuring all elements are compatible from the start minimizes potential issues later on.

Noise and vibration are also problematic in electric drives. These factors not only affect user experience but may also indicate underlying mechanical problems. Regular maintenance checks help identify these concerns early.

Software integration remains a hurdle as electric drive technology evolves rapidly. Keeping firmware updated ensures smooth communication between components and enhances overall performance reliability.

Future of Electric Drive Systems and Emerging Technologies

The future of electric drive systems is bright and full of innovation. Advancements in battery technology are paving the way for longer ranges and faster charging times. This will enhance the performance of electric vehicles and other applications relying on these systems.

Wireless power transfer is gaining traction, allowing for seamless energy transmission without cumbersome cables. Imagine vehicles that can charge while in motion or simply by parking over a charging pad.

Moreover, artificial intelligence and machine learning are starting to play significant roles. These technologies optimize system performance by predicting energy needs based on usage patterns.

Sustainability remains at the forefront too. New materials like biodegradable polymers may revolutionize component manufacturing, reducing environmental impact while maintaining efficiency.

With rising interest in autonomous driving, electric drive systems will integrate more sophisticated sensors and controls, enhancing safety features dramatically as we move forward into this exciting era.

Conclusion

Electric drive systems are rapidly reshaping industries and everyday life. The components—motors, controllers, and power supplies—are fundamental to these systems’ success. Each part plays a critical role in ensuring efficiency, reliability, and performance.

As technology advances, the significance of selecting the right components cannot be overstated. Properly integrated motors can enhance speed and torque while advanced controllers optimize energy usage. Power supplies ensure that everything operates smoothly without interruptions.

Challenges will always arise in any technological field. However, continuous innovation provides solutions to common issues associated with electric drive systems. As new materials and methods emerge, we can expect even greater improvements.

The future is bright for electric drive systems as they evolve alongside emerging technologies like artificial intelligence and IoT integration. These advancements promise not only enhanced performance but also increased accessibility for various applications across different sectors.

Embracing this evolution means recognizing the importance of each component within electric drive systems. Making informed choices today will pave the way for more efficient tomorrow.